Product Intruction(产品介绍)

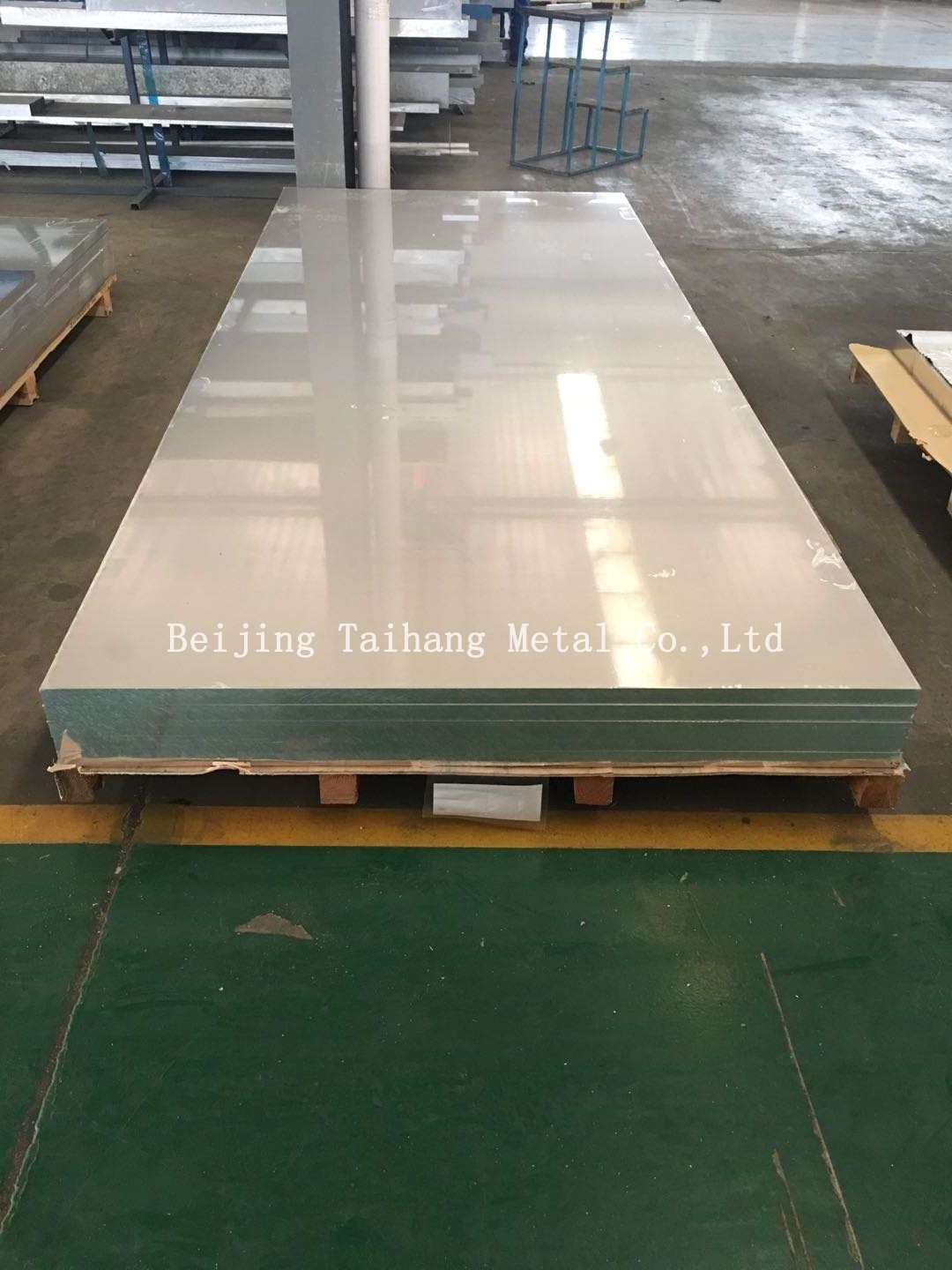

7075 aluminum alloy is a cold treatment forged alloy; with temper T651, its internal stress has been eliminated and it will not deform and warp after machining; all super size & thickness 7075 aluminum plates have been tested by supersonic wave so as to guarantee that there is no trachoma & impurity; it has high heat conductivity which can reduce shaping time and improve work efficiency; it contains Zn used for aerospace industry, belonging to Al-Zn-Mg-Cu alloy; it is of hard aluminum alloy, with good abrasive property; it can reach to extremely high strength by heat treatment.

Chemical Composition(%)(化学成分)

Alloy | Si | Fe | Cu | Mg | Mn | Cr | Zn | Ti | Zr | Fe+Ni | Others In total | Al |

7075 | 0.4 | 0.5 | 1.2-2.0 | 2.1-2.9 | 0.3 | 0.18-0.28 | 5.1-6.1 | 0.2 | -- | ----- | 0.15 | Remainder |

Mechanical Property:(机械性能)

Tensile Strength ?b( MPa): ≥540

Yiled Strength ?0.2(MPa): ≥460

Elongation δ5(%): ≥8

HB: 135-160

Product Features(产品特征)

1. Superior machinability;

2. Good polishing property;

3. High strength;

4. Applicable to electron beam welding & resistance welding, yet limited welding ability;

Typical Use(用途)

7075-T651 aluminum plate is mainly used in aircraft truss, industrial fixtures, railway traffic, mechanical engineering, automotive, industrial equipment.

Custom Service: 022-29302709 18526253017 1826253018Copyright:Beijing Taihang Metal CO.,LTD.

technical support:China website hosting base